#05_DANFOSS_B

Vision for Fastening Case

Context

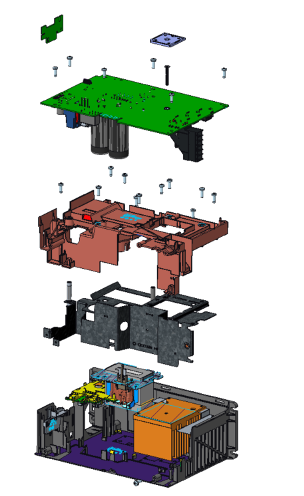

One of the main processes in Danfoss Drives’ factories is the assembly of frequency converters. This involves stacking components and fastening them with different types of screws. Screw fastening accounts for nearly half of the assembly time and is also crucial for quality and process control. This is why there is a strong focus on this process and an increased need for automation to make production more efficient.

In addition to using commercially available automatic screwdriver solutions, Danfoss is currently developing an in-house solution consisting of an intelligent screwdriver, typically used in manual production, attached to a collaborative robot (UR10e). The aim of this setup is to integrate automated fastening into manual assembly processes and create a cost-efficient, scalable solution for Danfoss Drives factories and other sites.

Challenge

The cobot-fastening setup is currently implemented for two products. For these products, all screw positions are hard-coded, which has several disadvantages:

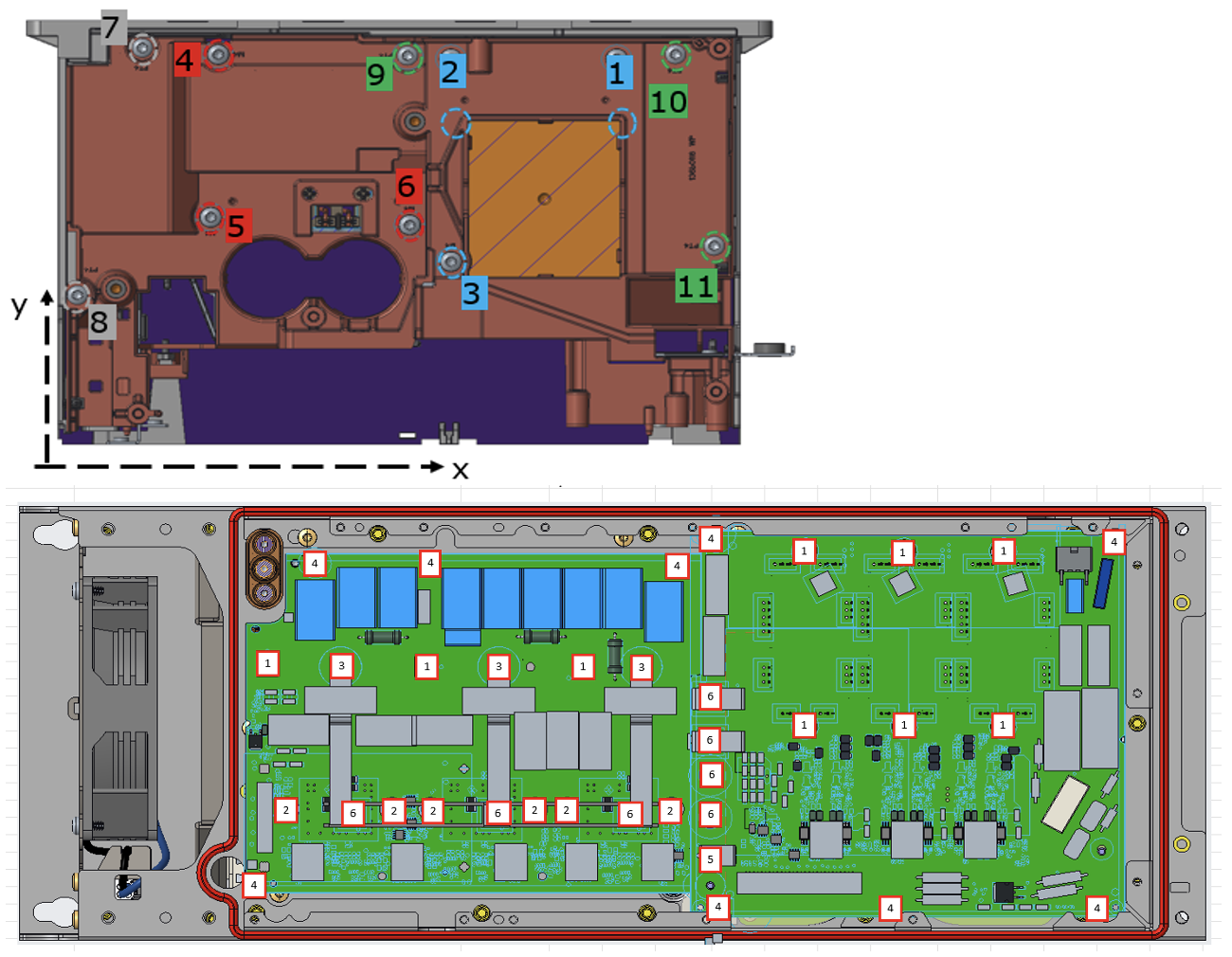

- Low scalability: Setting up a new product or product variant is very time consuming, as depending on the product, 30–60 screw positions need to be hard-coded, tested and run in. Therefore, it is currently time intense to scale up the setup.

- Low robustness against tolerances: Due to the products’ stacked design, long tolerance chains present a significant challenge. This can result in screw hole deviation of more than 1 mm in a worst-case scenario, leading to fastening errors such as cross-threading in production. It is not possible to compensate for these tolerances using hard-coded screw hole positions.

- Low robustness against variation over time: Many of the components supplied by vendors are produced in batches. Deviations between the batches lead to a shift in screw positions over time. This requires periodic reprogramming of screw positions, which is currently done manually.

The aim of the challenge is therefore to move away from hard-coding screw positions and create a vision solution to accurately detect screw holes instead.

Tools, methods and materials

Physical parts of frequency converters, CAD data

Ideal outcome for the company

Building up an intelligent vision system that can localize the screwholes with an accuracy of < 1mm, using one or two cameras.

The cycle time of the fastening process should not be increased by more then 3 seconds.