#08_LEGO_C

Dynamic gripper design

Context

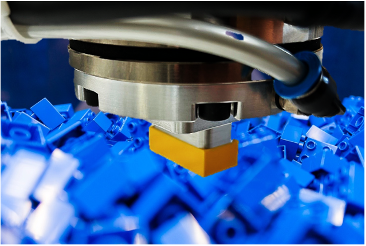

At the LEGO group, our bricks are primarily created through the process of injection moulding. This ensures a precise and clean product after just one process. However, some of our elements require a post processing procedure, like printing, to ensure the highest level of quality and detail. To enable the printing process, it is crucial to constrain the elements in custom jigs, to guarantee that the prints are correctly aligned and printed. This process of constraining the elements is very challenging as almost all elements are produced and stored in large disorderly quantities in containers.

A large part of constraining the elements is handling them with a gripper.

Handling is all the technology related to picking and placing the elements from our vibration tables to custom made jigs to ready the elements for processing. Specifically, the technologies related to the design of the grippers and jigs. The jigs which the elements are placing in, are also made specifically for each type of element, and only supports one orientation. A hard requirement for any gripper/jig, is that it cannot induce any unnecessary stress on the elements, nor can it scratch or deform them.

Challenge

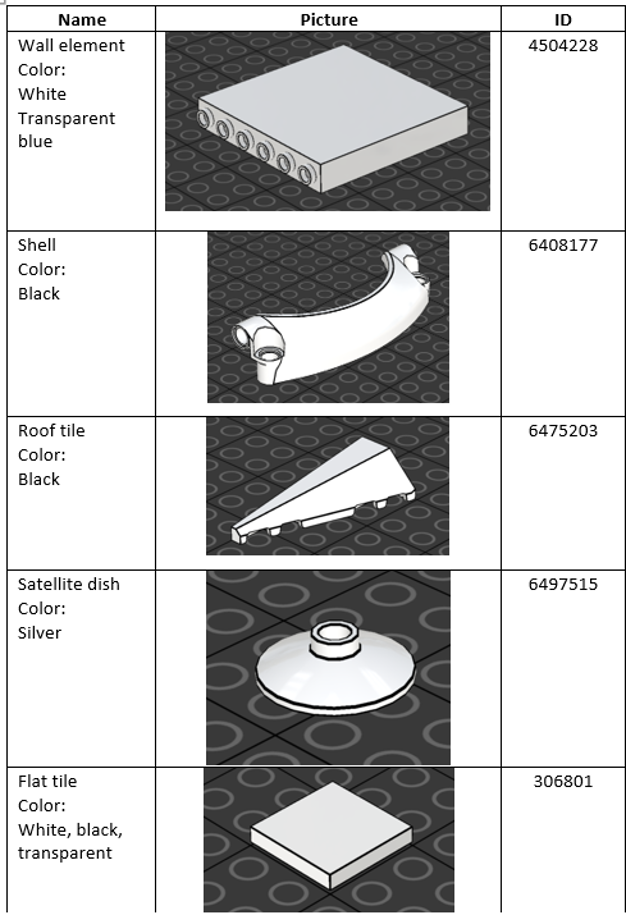

Develop a(multiple) gripper design(s) for a specific set of elements.

The gripper design(s) should be able to handle as many elements as possible to reduce the need for changeover. When the elements are picked, they should be correctly placed in jigs with the same correct orientation. It is allowed to create more than one design.

It is not a hard requirement that the design(s) are/is produced. However, if possible, consider doing so to verify that the design(s) work in practice. The gripper should be designed for a 4 DoF SCARA robot.

Tools, methods and materials

- Documentation of all the equipment

- CAD files for relevant equipment and elements

Ideal outcome for the company

A new gripper concept and hopefully a dynamic design process which we can replicate to develop more designs in the future.