#11_LINAK_A

Gripper design

Context

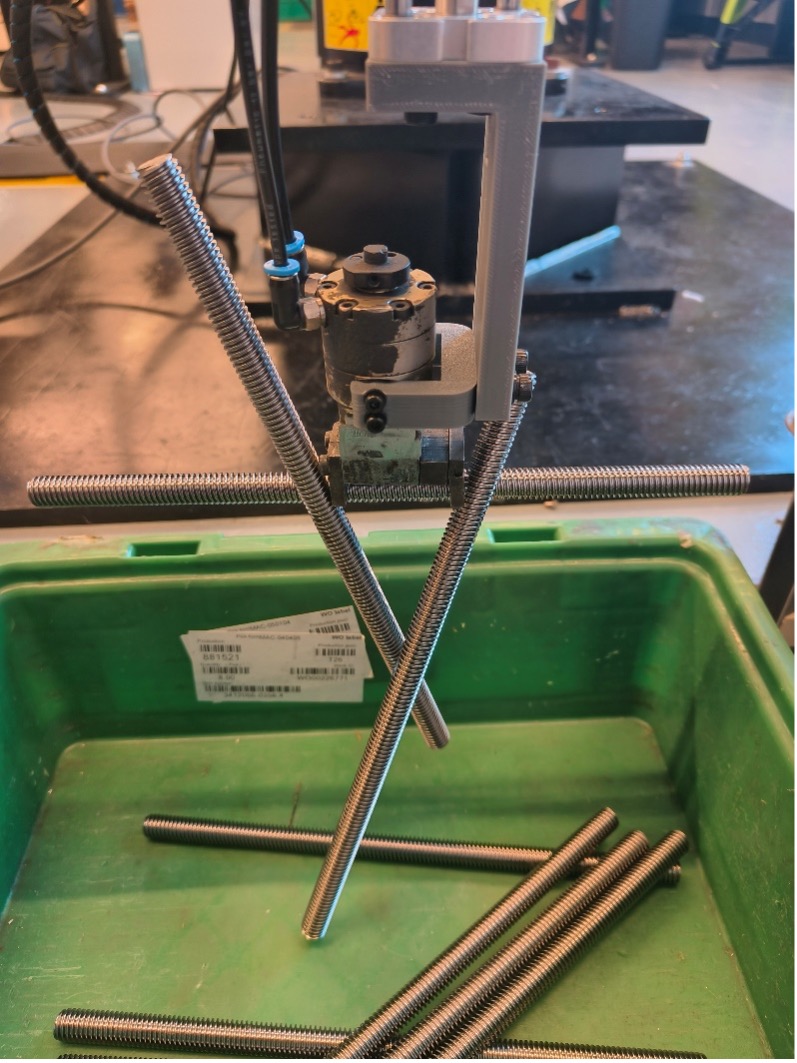

LINAK manually moves single spindles from wooden crates or other bins into a fixture on a pallet, which is then transferred to our automated production lines. This process is considered inefficient, repetitive and un-ergonomic for the operator.

Challenge

The challenge is to design a gripper that can pick up the spindles while ensuring that only one spindle is picked up at a time and that the gripper assists in aligning the spindle. Ideally, the gripper design should be capable of both picking up the spindles from a box and placing them into the fixture shown on the picture above.

To save effort and materials, the challenge is to be solved in simulation.

Tools, methods and materials

- Metal rods in the right dimension

- Dimensions of the crate/box the parts arrive in

Ideal outcome for the company

A concept for a gripper design, complete with CAD data, that can ideally be used to grip the spindle from the box and place it in the fixture.